[disclaim]Update: Since writing this post, I’ve had a few occasions where the Plasti-dip coating peels off while inserting it into wire channeling. (The same with Household Goop.) Lately I have been trying heat shrink tubing as suggested in the comments below. I don’t file the edge of the wire, since the tubing seems to form enough of a smooth edge. You can find heat shrink tubing at hardware stores. I purchased mine on Amazon.com. The 3/32″ size seems to work with most wires.[/disclaim]

When I first started making bras, I was surprised by the discovery that no two underwires are the same. I simply thought I’d buy a wire in my current size and presto!–I’d have one that fit just like my store-bought bras. But when I started taking apart my old bras I discovered that they were different in widths/diameters, curve shapes, lengths, and wire gauges. Some were really lightweight steel, others quite thick.

Underwires are the foundation of modern bra drafting. They determine breast diameter, circumference, and depth, and lingerie companies don’t go around picking wires out of a pile. There are a lot of specs and sizing research that go into wire manufacturing. What brands design depends on the style, their target demographic, costs and fit profiles. I’ve been on the phone with a few manufacturers and the choices are mind-blowing if I wanted to make them to order. So are the costs for a small independent retailer. I mention all this because it puts my attempts to find the “perfect” wire into perspective! It also makes me thankful for the independent shops that continue to source them.

And even though many shops now carry a variety of different wire sizes and shapes from plunge to strapless, I’ve been wanting to just cut my own. One of my favorite handmade bras recently bit the dust, so I pulled out the wire and found it rather out of shape…

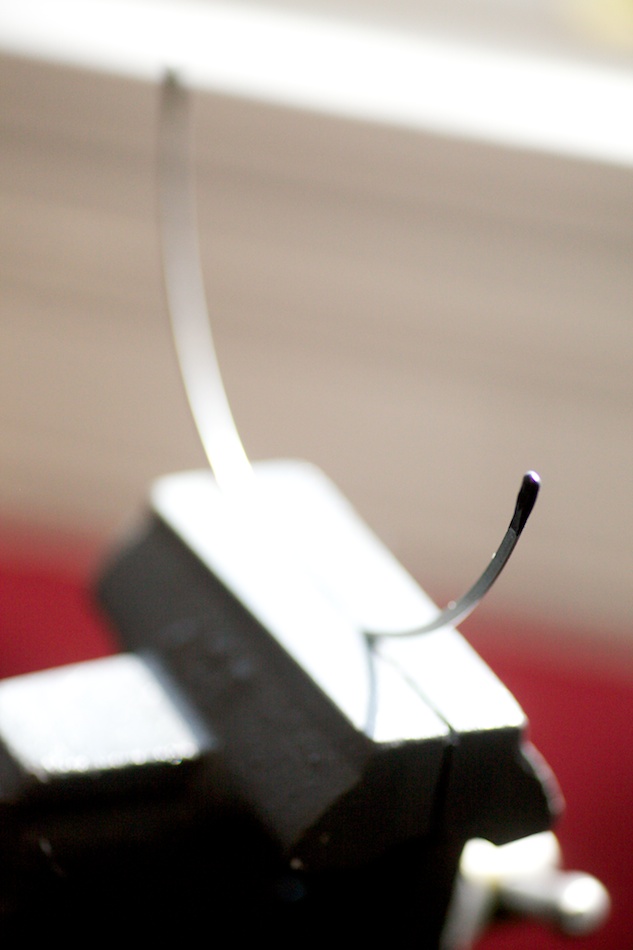

I cut it out because I really wanted to trace it off, before it got too late to discern any possible shape. The builders at my local hardware store directed me to copper wire cutters which would be great for picture-hanging wire but not the wires I’m cutting. I already talk about lingerie far more than is publicly acceptable so I had to make up something about “really thick steel jewelry!” to tell them why I needed a vise and plumber’s cutters!

The vice and cutters cost me about $15 total. I needed the cutters anyway, because I do cut jewelry chains occasionally.

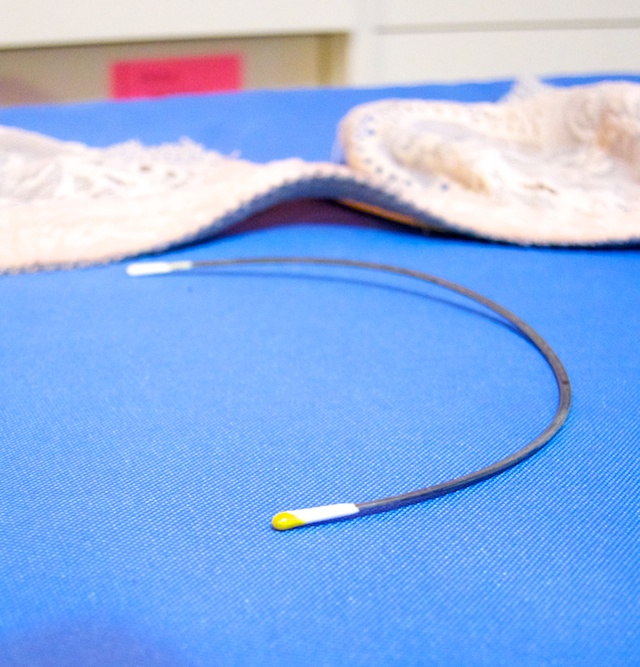

It’s very easy to cut existing wires. If the wires you bought are too long, even just a smidge in the front or sides, you feel it, right? Why not have a totally customized wire? Just mark off the spot you want the wire to end and snip. Definitely wear glasses for this–the snipped part will fly across the room! Here’s a set of wires, one before cutting and after (black tips). I took off about 3/8″ on each side.

To coat the wire ends, I used Plasti-Dip. Plasti-whaa, you say?

It’s basically a liquid rubber tool dip, and makes a perfect soft coating for the end of cut wires. It first became popular as a colored rubber coating for tool handles and auto wheel rims. A design-savvy friend informs me that dip-painting silverware was all the rage last summer, right next to overdyed Oriental rugs. Plasti-dip latched onto this trend and has a Pinterest board devoted to crafty dipping ideas. Chairs, jewelry, toothbrushes, kitchen appliances, shoes (great if you wanted some Comic-Con boots). Stopping short of small pets, it seems everything was getting dip-dyed. Or dip-rubbered, that is.

I also tried Household Goop, which I’d read about on a few corset-maker sites (it’s often used to tip bones), but I found it a little difficult not to “goop” a big messy blob on the end of the wire. If you make a mistake, both the Goop and Plasti-Dip are easy to peel off after a few picks with a utility knife.

Even though wires are invisible, I’m kind of a color fanatic. I like the idea of dipping my wires in a fun color, and Plasti-dip has a color mixing kit, which I bought because I think I’m going on a silverware dipping binge at some point! It took two or three dips to get a nice smooth end that properly covered the raw metal:

Presto–my perfect wire!

One more tip for using Plasti-dip: Once you dip your wires, it starts to dry rather quickly but takes about an hour for the dip to fully settle and dry. Find a way to hang your wires upside down, so that the dip forms a nice rounded edge at the tips.

Would you like tips and inspiration in the craft of lingerie sewing? Sign up for my weekly eletter The Lingerie Maker.

I absolutely LOVE this idea!! Is there any way of making our own underwires? It looks like it should be fairly easy to do, if we were to use an underwire that fit properly, from a worn out bra– especially if we already need the tools and PlastiDip to shorten them. What type of “wire” would we need to buy? I imagine a hardware store or lumberyard would have the wire??

I’m sure people have tried! Even the lightest underwire is a fairly thick steel gauge and would probably take heat to bend them into a good, permanent shape. Anything that was “workable” like jewelry wire would be too flimsy. Any metalsmiths out there? 😉

What a coincidence! I just cut a pair of underwires today! Well, actually, I didn’t and that’s because I couldn’t. I wish I could have video taped myself trying to cut those things last night because I’m sure I would have given you a good laugh! I spent a good half hour to hour clasping those pair of wire cutters with all my might. I even stepped on it. Nothing would cut those babies. When I asked one of my coworkers, a male, to cut it for me today, you should have seen his face when he realized they were bra underwires!

That’s hilarious! I did something similar the first time I cut jewelry chain. I bought really light cutters and I swear I was wrestling the chain on the floor. Derek came in on me and was like what the heck are you doing in here?! The linesman pliers will cut the wire in one snap. Here are the cutters I got from my store.

What an interesting post – thanks. I too thought that bra wires were generic so to speak. I love your thoroughness and research, I find it very helpful as well as enjoying your adventures.

Great information. I’ve shortened underwires before but always had trouble finding something to put on the sharp ends. I’m full-busted, so I need larger underwires, but I’m short-waisted and high-busted, so they usually end up poking me under the arms.

Me too! (Short waisted, small but high bust.) Wires really poke me under the arms. Strapless bras are the worst! Sometimes even 1/4″ taken off the ends makes a massive comfort difference.

Chances are your bra may be to large around your chest, which also makes for a wider cup.

Suggestion: Try a smaller chest size, with a larger cup.

If you find a cup size which fits (without the wires poking you under the arm) but the chest size is too small, you can always add a bra extender.

Cool expedition: the crossover between lingerie and Home Depot! I like how you went all the way and got the color kit instead of sticking with the black.

I really want to try sewing lingerie but the underwires have me so nervous! Thank you for posting this. 🙂

ok, i’ve used the plastidip to tip some wires that i shortened, but i found it to be too soft and rubbery, it peeled off while i was working it back into place. any suggestions?

Hi Lois, that’s strange. Sorry to hear that happened. This was the problem I was having with Household Goop! The Plasti-dip feels just a bit rubbery but it hasn’t peeled on me yet and I’ve used it on several pairs of wires. It feels dry after an hour or so, but I also didn’t use the wires for several days so perhaps mine hardened more after that. Did you try leaving it to dry overnight to see if that helps? Or perhaps something oily was on the surface of your wire before you dipped. Hmmm, people use this to paint auto wheels so there has to be a secret!

Got to get my hands on that Plasti Dip! I’ve heard all about it but never knew what it was called. Glad to see it used in sewing.

We stopped using Household Goop ages ago when we discovered heat shrink tubing. Cut the wires as you normally do but then put a short piece (about 5/8″ or 15 mm) of heat shrink tubing over the cut end. Heat with a heat gun or over a stove element. The shrink tube will shrink to the size of the wire and grip it forever. You can’t pull it off which is good! heat shrink tubing is available at electronics stores or at http://www.bramakers.com

Great idea, Beverly, and thanks for stopping by!

Just wondering can you use a blow dryer?

Hi Sharon, I tried a hairdryer but it was too much heat everywhere so I always use a simple lighter!

I hold the flame an inch away–not too close or the material will burn and it takes about 3 seconds for the tubing to shrink, unlike a hair dryer which took longer because I had to hold it further away. A lighter puts the heat source exactly where you want it so it does the job cheaply. If you have one of those long handle lighters for lighting candles and fires that might be easier to use if you are worried about burning yourself. 🙂

Amy

So after read this and trying our small lightweight cutters, I enlisted my husband for help and he enlisted our next door neighbor who is a mechanic. How embarrassing! But they got it done. They cut a little bit then used pliers to work the rest off. And then he had a metal grinder and made the edges smooth. My husband decided to tell him what they were of course aack!

I think I’ll buy some cutters but try his method of working the underwire off as I’m afraid of snapping things off and having them hurt someone. Thanks for the idea!

Hi, that’s a funny story! it’s really easy to use the plumbers cutters–they were about $10-15–and they’re good to have around if you make jewelry, too! (I’ve used it to cut hanging chains for jackets and shorten jeans rivets…) As you discovered, lightweight cutters are only good for things like thin copper wire or guitar strings and you have to work them to go through anything thicker. I’ve cut a lot of underwires now, and the ends snap off in one firm click. They do go flying but I do this in a closed room, with my glasses on. It’s not dangerous as long as you protect your eyes like you would cutting any metal ;).

I managed to cut my underwires with a bolt cutter (in a room with some safety goggles like you) but the plasti dip didn’t work for me either. I ended up sanding the ends. I am getting some digging from the wires. It’s because I had to cut off like an inch and a half and now the end I cut slightly bends in toward my body. I’m thinking if the gore were lower this might eliminate it but for now I’m thinking of adding some felt to relieve the pressure. This will save so many bras for me though I’m glad I found this or otherwise I may not have tried it 🙂

Awesome! Since I wrote this post, I’ve had a few troubles with plasti-dip so I may have to update it soon. It stays on some underwires; others it does not and easily slips off. Now I think I’m going to plasti-dip my old silverware because I have so much of it! 😉 If filing down underwires gets old, you may want to try using the heat-shrink tubing like Beverly Johnson suggested in a previous comment. (You can buy little strips of it for as little as $2 on Amazon or a hardware store.) I tried it and so far it does not slip off any of my wires.

And you’ve also discovered the tricky thing with underwire curves and cutting. I only cut about 3/8″ off the front. If you prefer really short wires, you may want to look into plunge wires of some sort. Almost all bra-making supply sellers offer some. They’re designed to be lower so the front end doesn’t “curve in”.

Also when you say the front do you mean the part that goes under your arms?

I will definitely try the heat shrink tubing at least once to see if it can add some comfort so I don’t have to sew on some felt. I just have really high set boobs and a short torso (though I’m 5″7 so just unlucky I guess) and Panache’s underwires are generally in my armpit.

Actually I was thinking of pulling the underwire channel off and slipping in some underwires from another bra because I really need narrow, short wires that simply aren’t available in my size at the moment.

Do you know if it’s possible to just take off the underwire channel, put a new underwire in and resew back onto a pre-made bra without any weird issues? I was going to try it but haven’t gotten around to it yet. Also I noticed that the Bra Makers Supply (which is awesome btw, thanks so much for sharing) doesn’t seem to say width on their wires anywhere so I was hesitant to buy any underwires from them.

Hi… yes I am all too familiar with being high busted. A lot of wires are too long for me. In the above comment I was talking about the front part–not the “tail” (under the arms).If the wire is poking into my breast on the side under the arm, I go up a size in wire. (Sometimes that extra 1/4″ makes all the difference in comfort.) I’d probably give a phone call to Bra-makers–they’ll have more info on lengths and widths… and sometimes they don’t have all their inventory listed on their site. They are one of the few sellers that offer “vertical” wires that are narrower.

Replacing wires… why not? a worthy experiment if you love your bras…The hard part will be unpicking the elastic and bartack stitches that closes the channeling. Or you could cut a slit in the channeling but then you’d have to find a way to shut that hole. Putting new channeling in would be a lot of work… not impossible but just a lot of stitching that needs to come out. (Having unstitched entire bras… wow, it took hours!)

I’ve been taking my wires to the local Home Depot hardware store. They have a special equipment box for cutting the chains they sell. I mark the wires where to cut. It takes him a quick set up and DONE. I don’t tell him what the wire is for. I’m just another satisfied customer.

Hi Barb, that’s a great idea!