I love making up sewing tools. There are times a tweezer works better than a bone folder, and a rubber hammer works better than an iron. I have a pencil that works great for spaghetti straps and probably do “wet finger” pressing on silk more times than I care to admit.

It’s really fun and easy to make your own pressing tools, and this week I’m pleased to share a guest tutorial on making your own bra pressing curve from my fellow lingerie-making addict Maddie Flanigan! You may know her from her blog Madalynne, gorgeous sewing photography and brand-new bra making workshops in her Philly studio. So let me step aside as Maddie brings on the drill…

——–

Based on a similar item sold at Bra-makers Supply, my bra pressing curve has become a

valuable tool. I first came across it when Beverly Johnson mentioned it during her class

on Craftsy. She said it was easy to make and she was right. All it took was a trip to the

hardware store and about 30 minutes. I use it mostly to press cross cup seams without

touching other parts of the bra.

Supplies:

All supplies except for round ball can be sourced at most hardware stores such as Home

Depot and Lowes.

- Power drill

- 3″ wood round ball

- 5.5″ x 5.5″ wood square

- 1 1/4″ diameter wood dowel

- Dowel center pins

- Brad point or dowelling drill bit

- Just like bra making, sourcing all those little bits can be intimidating. To make it easier, you can buy a dowel kit such as this one.

- Regular drill bit

- Pencil

- Masking or painters tape

- Wood glue

Prep: Most likely, your hardware store will sell long, rectangular pieces of wood, not one that is exactly 5.5″ x 5.5″. The same goes for dowels. Having it cut down isn’t a hassle. The hardware store should do it for free. Ask to have extras pieces cut so you have a spare in case you mess up.

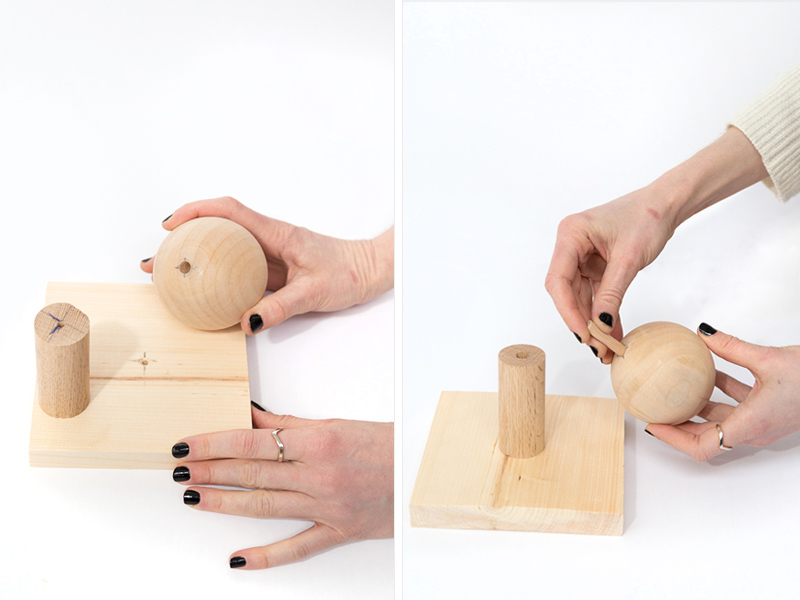

Step 1: Using a pencil, mark the center of the sphere, the center of the dowel at the top and bottom, and the center of the square at the top and bottom as well. Mark all of these points with a cross mark.

Step 2: Mark the center of the dowel pin and then place it next to the drill bit as shown. Using masking or painters tape, wrap the drill bit at the point where the center point is on the dowel pin. Why? Because you don’t want to drill too far into the ball or the dowel.

Step 3: Use power drill to drill a hole into the ball and the dowel at both top and bottom. To ensure that you drill straight down, use a quick grip clamp or have someone hold the ball and the dowel while you drill.

Step 4: Connect the ball with the dowel by placing a thin coat of wood glue on the dowel pin and inserting one end into the ball and the other into one end of the dowel.

Step 5: The final step is to connect the dowel/sphere (which is now one) to the wood square. Using a regular drill bit, drill from the bottom of the square block up through the bottom of the down with a regular screw.

Would you like tips and inspiration in the craft of lingerie sewing? Sign up for my weekly eletter The Lingerie Maker.

Thanks for the opportunity to share this tutorial. I hope others find it useful in their bra making!

Neat! I can see other uses for such a thing, and I do love all my wooden pressing tools…but did I miss a link to wooden ball sources? As you suggest, I’ve not seen anything like that at my hardware store. Thanks! Also, I bet I’m not the only lazy reader thinking that the ball would probably be almost as useful a pressing aid without any stand!

You can purchase the wooden ball on Amazon: http://www.amazon.com/gp/aw/d/B0054G6B08/ref=mp_s_a_1_1?qid=1424213461&sr=8-1&keywords=3%22+wooden+ball&dpPl=1&dpID=41fpMgBI3fL&ref=plSrch&pi=AC_SY200_QL40

Perfect; thanks!

You can also use the wooden finials that you find on top of fence posts. They are sold at Home Depot and other hard wear stores.

I just press my bras on a tennis ball. 🙂

I am taking Leah’s advice and going with the finial/round post cap. A square post cap will be the base. One longish wood screw and a bit of wood glue to attach part A to part B.

I found some cheap post ends at Lowe’s.

https://tinyurl.com/ybxzoalr

https://tinyurl.com/yb2ln796

No, you’re not the only one–I can think of a million pressing reasons for either the ball or a long dowels!

I’ve got a split-lenthwise 1 ½-in. dowel in hardwood called a Seam Stick, about 2-ft. long, all nicely sanded but unfinished that’s perfect for long trouser-seam pressing. And I’ve seen that Kenneth King uses a length of un-finished hardwood stair-railing for the same purpose, much bigger and heavier, which might be a plus or a minus… I think the hardwood issue is rather critical (I guess birch is one? the balls are birch); everything I’ve ever seen made of wood for pressing has been so described, so probably hardware store dowels, which I think are fir, aren’t the best…?

Just a thought… I wonder if anyone has tried steaming/shaping their own molded bra cups either with foam or fabric. I think this is one of the techniques that is demonstrated on this tool in the Bra-makers Manual. I don’t usually make molded foam bras but I wonder if others have tried it or are interested in that?

Hi Amy,

I am surprised no-one replied to you.

I have not tried this – yet, but I did read somewhere that you can do this with your iron. I would imaging you would be using just the steam, not the actual sole plate since you don’t want to melt or compress the foam. Similar to molding shoulder pads, is my guess.

I really should to a test with my seam roll and report back.

But you have me convinced that seamed cups are the way to go, so I don’t want to use any of my foam for anything else 🙂

Hi Nia, I had comments turned off for awhile so this might be why there weren’t responses. 🙂 Sounds like a fun experiment!

This is so incredibly helpful!