I’m making a new lingerie set using this funky yellow zebra lace from Merckwaerdigh. I find animal prints hard to resist and this one is so soft, feminine and subtle. But to make a bra from this set I have to make some pattern adjustments to the band. The matching lycra is a super stretchy 4-way lycra/spandex fabric, and if you have ever tried to make bras with new band fabrics you probably figured out that no two band fabrics fit alike!

If you were to take apart a few of your RTW bras and detach the elastic, you’d notice the bands are all different lengths. This doesn’t necessarily mean they are different band sizes, just that they were drafted with the negative ease particularly needed for that fabric. Unfortunately, most commercial patterns aren’t always clear on the stretch percent or type of stretch for which they were drafted, probably to allow for the widest interpretation possible.

There is a way to get around all this without worrying about sizes. I like to adjust my band pieces for each bra using just a little bit of math. It’s easy math, I promise!

{ONE} If you have already made a bra from your pattern, put on your bra and measure from the side seam of your bra around your back to the other side seam:

The line of the tape should be level with your underbust along the elastic hem. Try to hold the tape firmly–you want a firm number.

*If your pattern doesn’t have a side seam, you’ll need to measure from the side of your cup where the underwire is all the way around to the other side.

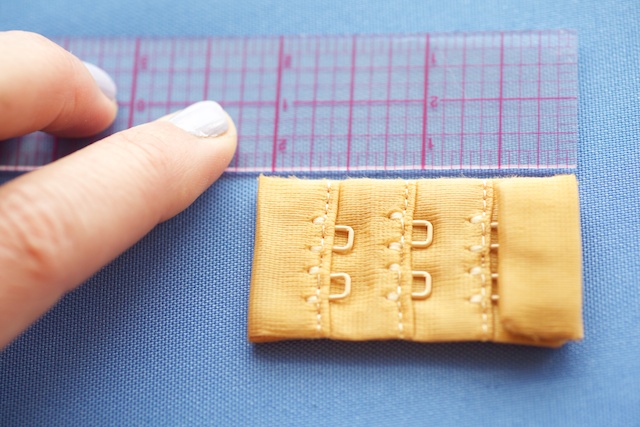

{TWO} Find the width of your bra back closure, with the closure on the loosest hook. Subtract this number from the back measurement you just took in step 1.

My Back Measurement 15 7/8″ – Closure Width 2 1/8 = 13.75″

Divide this number in half. This is the length of your bra band piece with no negative ease. Mine would be 6 7/8″. Now you need to adjust it for the stretch of your fabric.

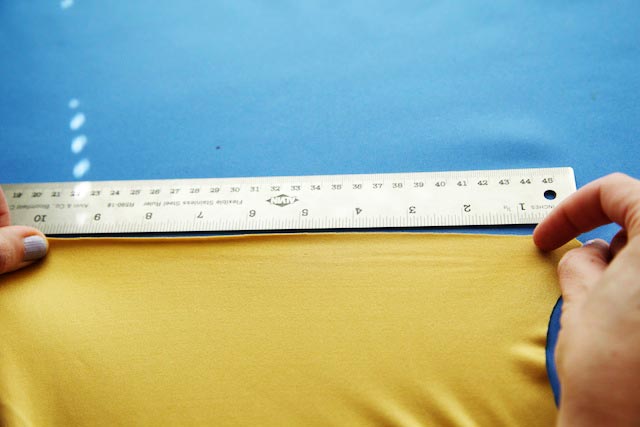

{THREE} Find out the stretch percent of your fabric. I first find the direction in which the fabric stretches the most, and take a length of about 5″ or 12cm and stretch it to its maximum along a ruler.

My lycra stretches from 5 to almost 10″, which is 100% stretch. The calculation: (5″ stretched / 5″ original length) x 100 = 100%.

Using your stretch percent, you can now make some logical adjustments to your band. Obviously the more a fabric stretches the shorter you want your band to be.

{FOUR} For band fabrics, I have found that reducing length by 3% for every 10% of stretch generally works. For example, if your fabric has a 75% stretch, then multiply 3 x 7.5 to get the stretch reduction of 22.5%. My lycra stretches almost 100%, so I multiply 3 x 10 to get a stretch reduction of 30%.

I take my measurement from step 2, and multiply it by 70%. (Reducing by 30%.)

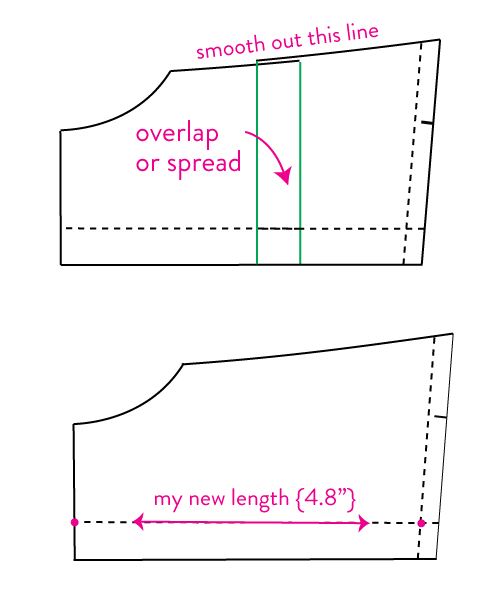

6.875 x .70 = 4.8″

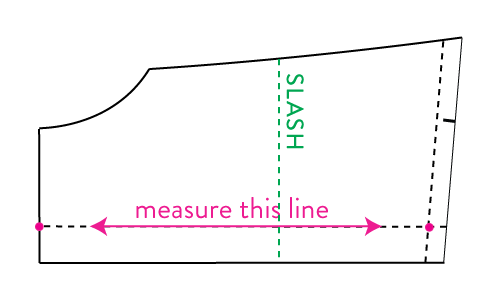

That is how long I want my new band piece to be along the hemline, from the stitching line of the side seam to the line where the back closure is sewn. My current band piece is 5.4″, which was a good fit in a heavier powernet.

To shorten this piece, I slash down the middle and overlap. until the new hem length reaches 4.8″. Then I retrace the band and smooth out the lines. Voila–a new band piece!

*Note that it’s important to take these measurements between the seam lines and not the edge of the seam allowance. Seam allowance doesn’t count toward length!

Of course math isn’t the whole story and there are other factors which will influence the fit, including how tightly you pull your elastic while sewing. But I have found this to be a good starting point so I don’t end up with too-loose bands. As always testing is always your best friend!

Would you like tips and inspiration in the craft of lingerie sewing? Sign up for my weekly eletter The Lingerie Maker.

This is so timely – I had just such an adjustment to make on a bra I was drafting from a RTW and couldn’t work out how to adjust for different banding. I am definitely saving this post. Thanks so much for all your help with bra making. I would never have had the nerve to try without your blog.

Thanks Maureen! I’m glad it helps.

Oh! Fantastic! Now I know why you needed to know the “stretchiness” of my fabric! Amy your attention to detail is very inspiring!

This post is very timely for me as well. I’ve bought kits with different band fabric than the kits I used during the sew-along. I knew I’d have to adjust the band pattern but wasn’t sure how I’d go about it. Now I know! Thanks for the logical steps.

Hi Lisa, glad it helped! I know your dilemma. My first couple of bras came out too big in the band because I started using different kits. Now I have like six band patterns that I can pull out for different fabrics. Saves me so much time!

Great post Amy! And I love that lace!

I remember this from Beverly Johnson’s manual except she refered to the measurement as upper back width. I’ve been meaning to go back to the manual and brush up on some bra making knowledge and this post made me pull out the book. Thanks!

P.S. Your explanation was way better (and clearer) than Beverly’s 🙂

Thanks Maddie. I started doing this before I had her book, but that was good because it forced me to test and come up with stretch reduction calculations. I was getting frustrated because most other bra drafting books just draft an arbitrary band length based on back width. 🙂

This is super helpful. Thanks for sharing!

Very useful! I have not got too adventurous with band fabrics, because of the variations it leads to in fit…now I’ll be good to go with all sorts of fabrics!

Hey Katherine, let me know how it works for you! I noticed that the Shin book drafts a longer band, so I wanted a way around it. Since I’m such a small cup I like very stretchy bands, so they need to be a lot shorter to fit.

I am really enjoying your tutorials and can’t wait for my first bra pattern to arrive.

This is so great Amy! I’ve been wondering about the different stretch factor and even considering to only use power net for the back band so all the bras I make will fit. Your technique makes more sense. Thank too so much!

Don’t you just love the bra kits Merckwaerdigh puts out? I have been getting around the stretch issue by underlining the band pieces in regular powernet, but this is a much more accurate method. Thanks for sharing!

Gorgeous. I need to start stalking the Merckwaerdigh sites more often so I can snap up a gem of a fabric like this! Thanks for the info 🙂